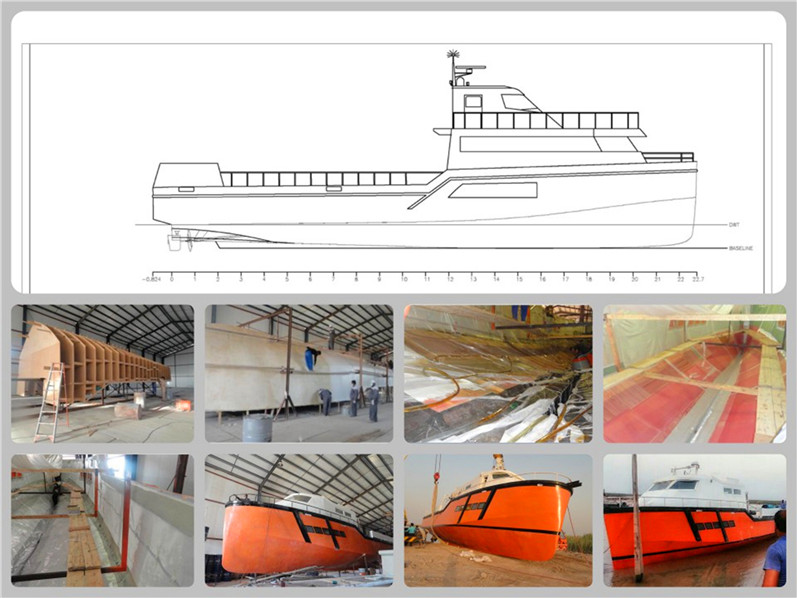

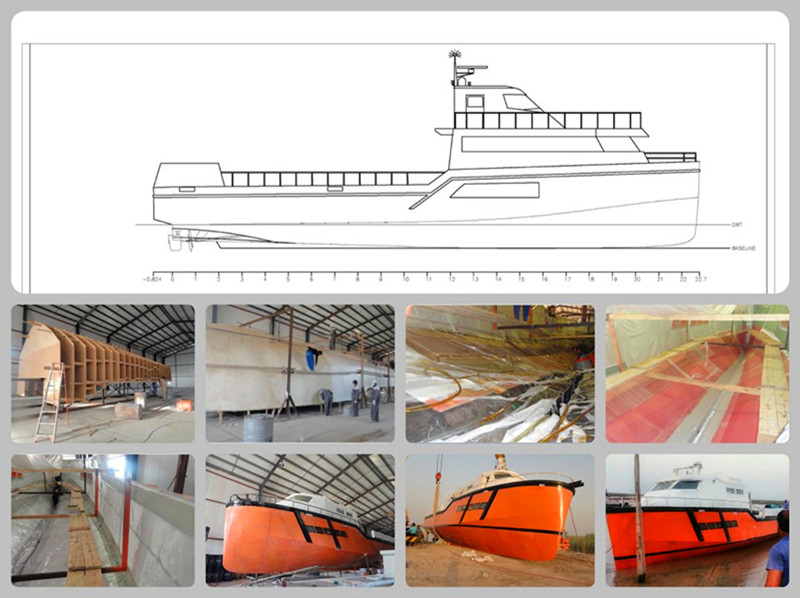

Fiberglass For Boat By Vacuum Infusion Process

Our customer design their ships after each clients specific needs and the ships are created using vacuum infusion. Vacuum infusion is a cost effective method for creating high quality composite parts and fiberglass. When designing ships, parts manufactured using the vacuum infusion process have better quality, better consistency, higher glass content, higher strength, better interior finish, better stiffness, faster cycle time and lower cost compared to the open mold process others in the region use.

This technology to create ships that are more cost effective whilst still being better for their respective needs than alternate methods.

The raw materials will be used:

1: woven roving 600gsm

2: chopped strand mat 300gsm and 450gsm

3: biaxial combination fabric 1250gsm

4: biaxial fabric 800gsm.

- Prev: FRP Tools For Pultrusion