Categories

Product features | Applications |

Excellent specific stiffness and specific strength Good fatigue and impact resistance Thermal insulation Low water absorption | Wind energy: Rotor blades, nacelles |

Product Description

Product Performance

Strucell P is a cross-linked rigid structural PVC foam material. Strucell P, as a close cell foam, based on vinyl polymer, modified with the throughout Aramids link. It is the compounding chemical material based on PVCand PUR. It is said as the cross-linked PVC foam core, in the international practice.

Strucell P can be used as the core material in the sandwich structure.

We accept customized type which used for special applications like luxury boat building, modular building,wind electricity...

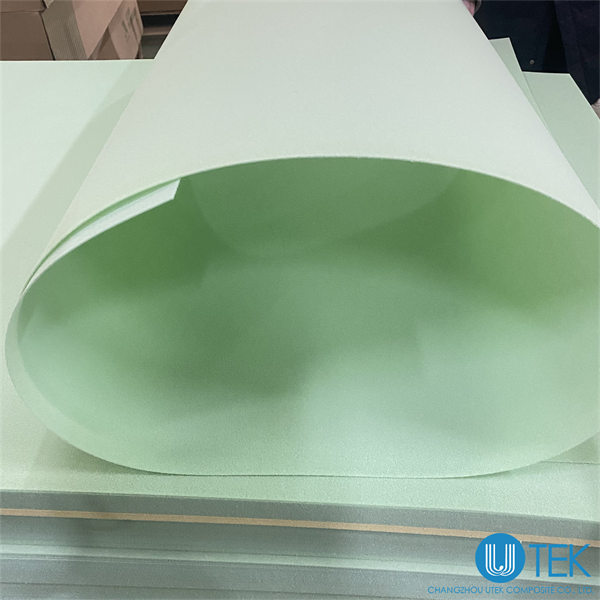

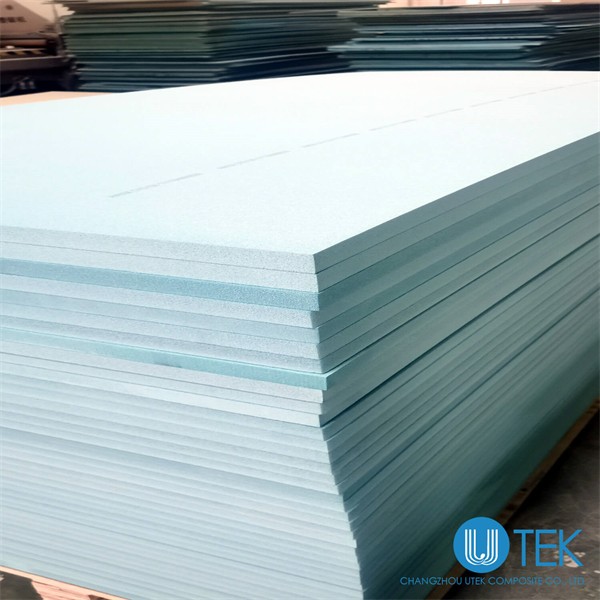

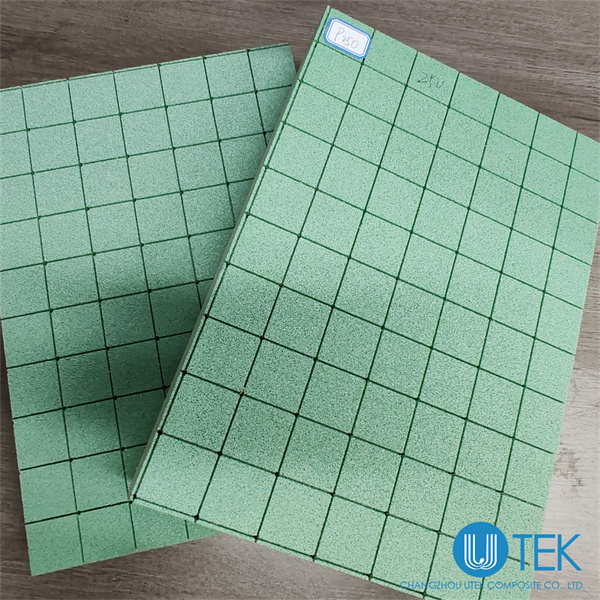

Product Picture

|  P60 |  P80 |  P100 |

P130 |  P200 |  P250 |  P300 |

Product Parameters

Item | Standard | Unit | P48 | P60 | P80 | P100 | P130 | P200 | P250 | |

Density | ISO 845 | Kg/m3 | Average | 48 | 60 | 80 | 100 | 130 | 200 | 250 |

Tolerance | 43-55 | -6,+9 | ±10 | ±10 | ±15 | ±20 | ±30 | |||

Compression Strength | ASTM D1621 • | MPa | Average | 0.60 | 0.9 | 1.4 | 2.0 | 3.0 | 4.8 | 6.2 |

Minimum | (0.50) | (0.7) | (1-15) | (1-65) | (2.4) | (4.2) | (NA) | |||

Compression Modulus | ASTM D 1621 | MPa | Average | 48 | 70 | 90 | 135 | 170 | 240 | 300 |

Minimum | (35) | (60) | (80) | (115) | (145) | (200) | (NA) | |||

Tensile Strength | ASTM D 1623 | MPa | Average | 0.95 | 1.8 | 2.5 | 3.5 | 4.8 | 7.1 | 9.2 |

Minimum | (0.8) | (1-5) | (2.2) | (2.5) | (3.5) | (6.3) | (NA) | |||

Tensile | ASTM D 1623 | MPa | Average | 35 | 75 | 95 | 130 | 175 | 250 | 320 |

Modulus | Minimum | (28) | (57) | (85) | (105) | (135) | (210) | (NA) | ||

Shear | ASTM C 273 | MPa | Average | 0.55 | 0.76 | 1.15 | 1.6 | 2.2 | 3.5 | 4.5 |

Strength | Minimum | (0.50) | (0.63) | (0.95) | (1.4) | (1.9) | (3.2) | (NA) | ||

Shear | ASTM C 273 | MPa | Average | 16 | 20 | 27 | 35 | 50 | 85 | 104 |

Modulus | Minimum | (14) | (16) | (23) | (28) | (40) | (75) | (NA) | ||

Shear Elongation | ASTM C 273 | % | Average Minimum | 10 (8) | 20 (10) | 30 (15) | 40 (25) | 40 (30) | 40 (30) | 40 (NA) |

Width | mm | ±5 | 1270 | 1120 | 1010 | 940 | 840 | 740 | 700 | |

Standard | Length | mm | ±5 | 2730 | 2350 | 2160 | 2040 | 1880 | 1600 | 1500 |

Size | Thickness | mm | ±0.5 | 5~80 | 5~70 | 3~65 | 3~60 | 3~50 | 3~40 | 3~40 |

Surface Treatment

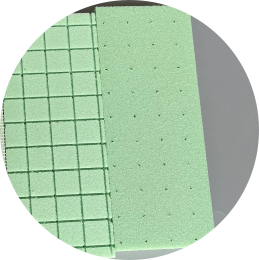

Plain/Flat |  Groove/Perforate |  Contour Board |

Application

|  |  |  |

|  |  |  |

Factory Tour

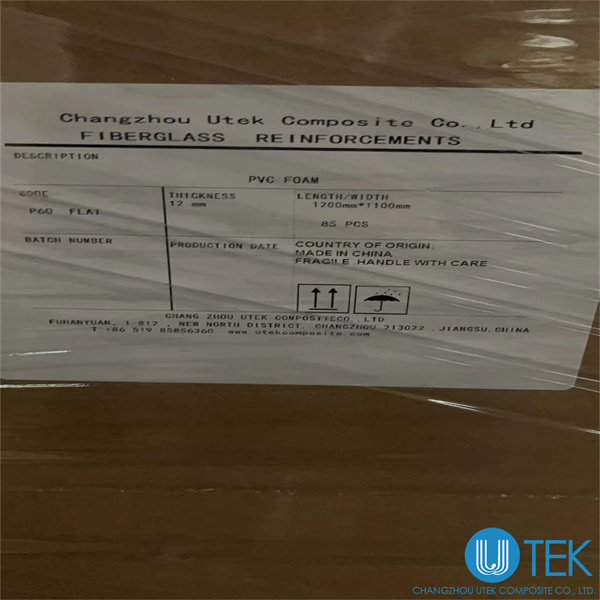

Block Storage |  PVC Foam Sheet Storage |  Label |  Packing |

Others

FRQ: Q1. What is your MOQ (minimum order quantity) of PVC foam? A: 10 pieces. Q2. How can I get a sample from you to check quality? A: Small quantity: 3-5days; Full container quantity: 15-20days. |