UTEK axial fan Design Validation Standard Test Results

UTEK axial fan Design Validation Standard Test Results

How to Prove Same Lay-out and Performance

* DV : Design Validation

* Comparison DV TEST has to be conducted between each WIingF sample given by customer and each Dele replacement fan.

* Visiting UTEK to review DV test result and Quality control System.

Comparison DV TEST ITEMs

* DV : Design Validation

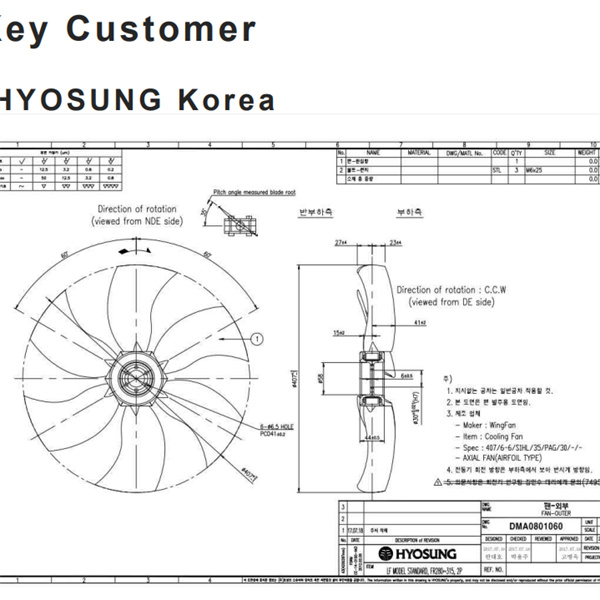

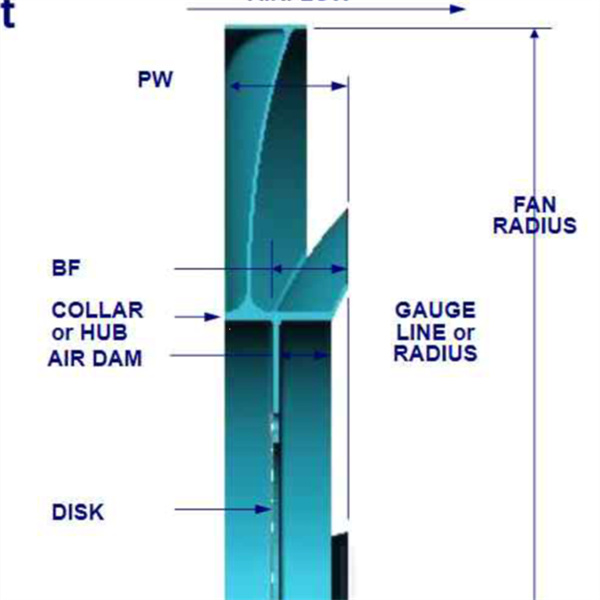

1. Dimensional each Wingfan and UTEK fan for the lay-out & raw material.

*Measure: Fan dia /PW/BF etc, and make comparison sheet

*Compare Blade raw material and use same raw material fan with wingf as test fan.

|

Comparison DV TEST ITEMs

2. Comparison Air Flow Test

*Test Method (procedure): to test at same test condition for each fan to see UTEK fan has same performance with Wingf sample.

*Acceptance Criteria: +/- 3~4% in Air flow -Measure power and Noise

|

Comparison DV TEST ITEMs

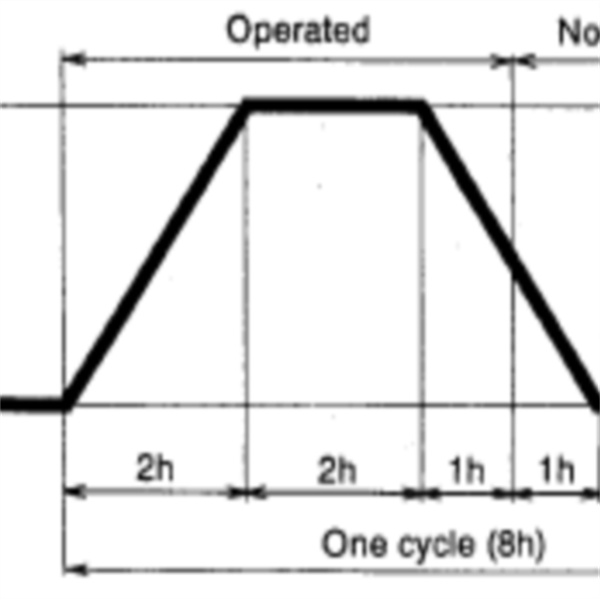

3. Thermal Cycle (Do conduct test with UTEK fan and Wingf sample together)

*Method: -Hgih Tepm :120˚C ± 2˚C at cold and hot chamber for 2h

-Low Temp : - 40˚C ± 2˚C at cold and hot chamber for 2h -8h is one cycle and 30 cycles has to be tested |

Test results:

No visual cracks and loosening of the metal disk. No color changed.

Do air flow test with tested fan again to see if the air flow is +/-5% between tested fan and not tested fan.

Comparison DV TEST ITEMs

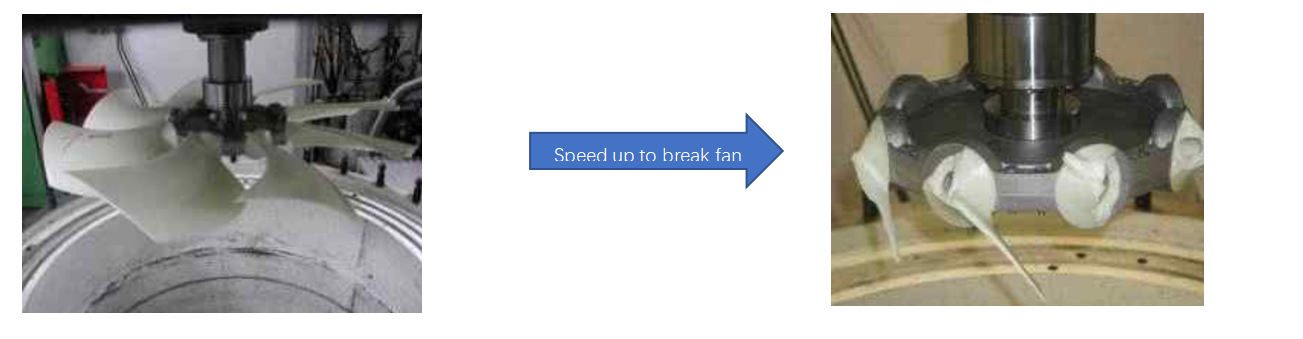

4. Spin burst test

- Method- * To speed up rpm of each Dele and Wingf until fan will be broken in 500rpm increments for 20 or 30sec to see each fan damaged or broken RPM. * If there is no safety issue, rotate fan up to 7000~7500RPM ( Fan dia : < 600 mm) , up tp 6000 RPM ( >600mm)

Comparison DV TEST ITEMs

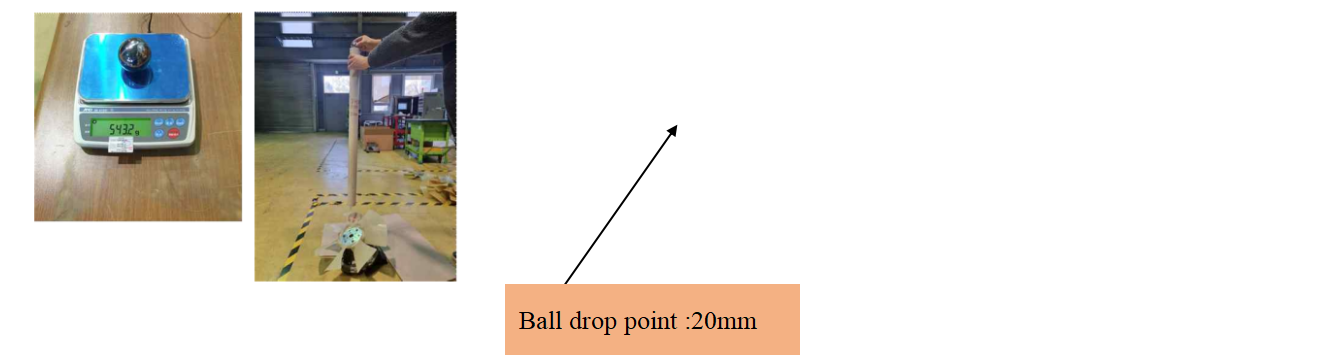

5.Cold impact

- Method- * Place each fan in the cold chamber at - 40˚C for 4 hrs Drop a 0.54kg steel ball from a height of 1.22M on each blade.

* Acceptance Criteria : - No visual cracks and loosening of the metal disk.

Comparison DV TEST ITEMs

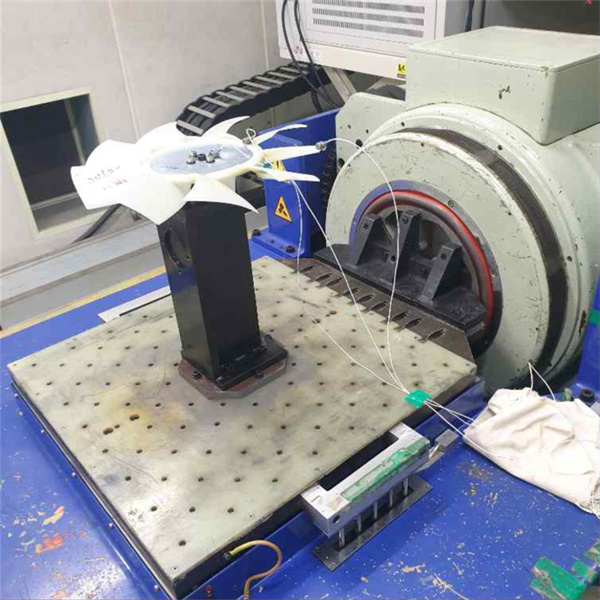

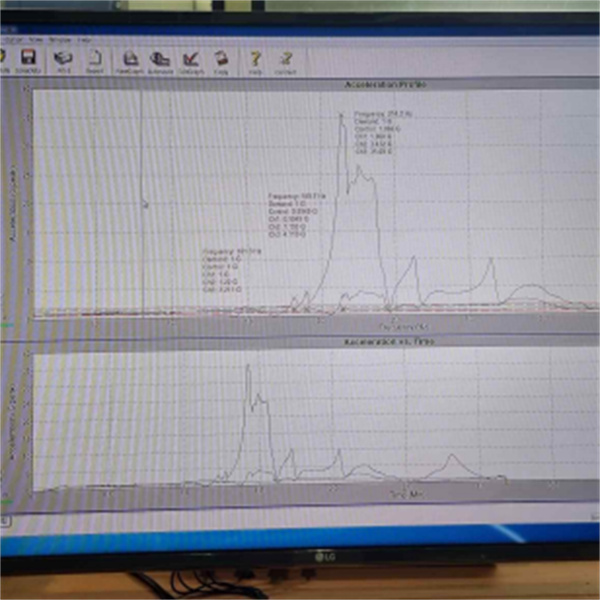

6.Resonance Test

- Method Sweep Frequency : 10-500Hz, 1G Accelometer(Response / sensor ) Position : Fan edge, hub, disk. |

Acceptance Criteria: To submit 1st / 2nd / 3rd Mode Frequency No 1st Mode less 100Hz or Wingf and UTEK same or similar resonance point. |

Comparison DV TEST ITEMs

7. High Speed Test

Method: To rotate fan in the 100˚C hot chamber at 3000~4000rpm for 100 hours. ( can test 8 hours a day for 10 or 15 days)

Do not need to test with Wingf. UTEK has only to est with UTEK fan which has same air flow with Wingf. |

Test result: No visual cracks and loosening of the metal disk