Hot Sale Synthetic Surfacing Veil for The FRP Industry

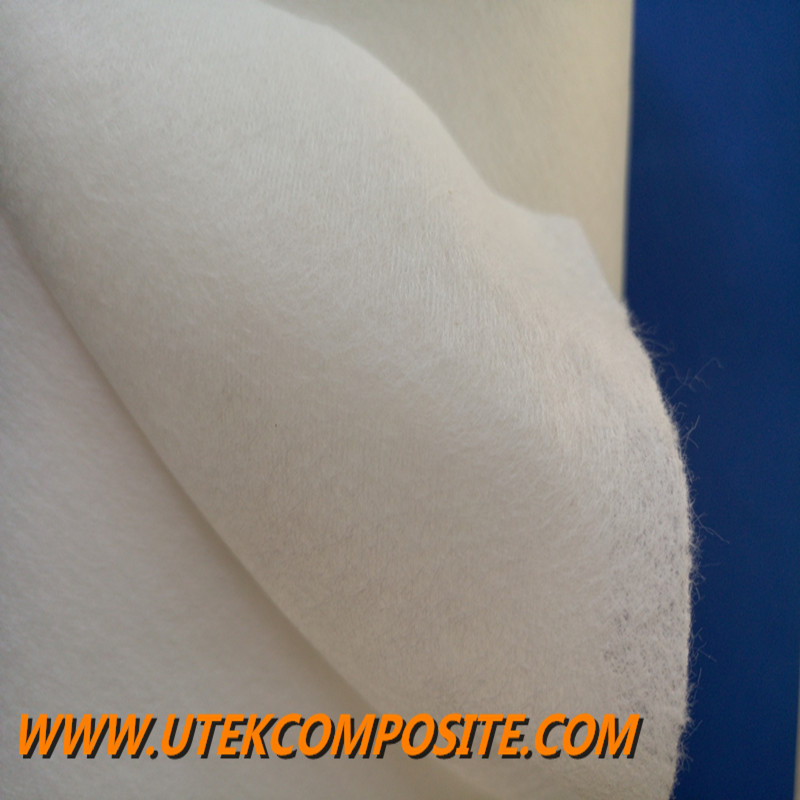

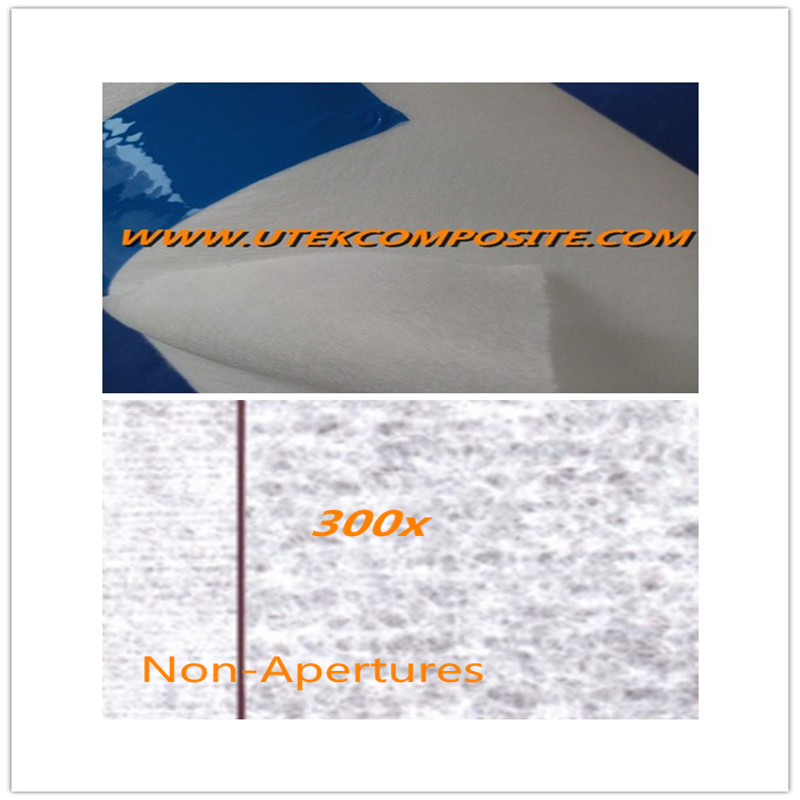

Non-Apertured Synthetic Surfacing Veil For the FRP Industry.Synthetic surfacing veils has becoming more and more popular due to its ease of processing, and it is heavily specified by architects, composite manufacturers, engineering firms, and resin producers.It’s not not just make your products better but also make the process easier.

Characteristics

1. 100% high melt polyester

2. Excellent appearance and surface smoothness

3. Hand can be customized to processing preference

4. Superior chemical and corrosion resistance

5. High tensile and tear strength

6. Widths from 1” to 170

Benefits:

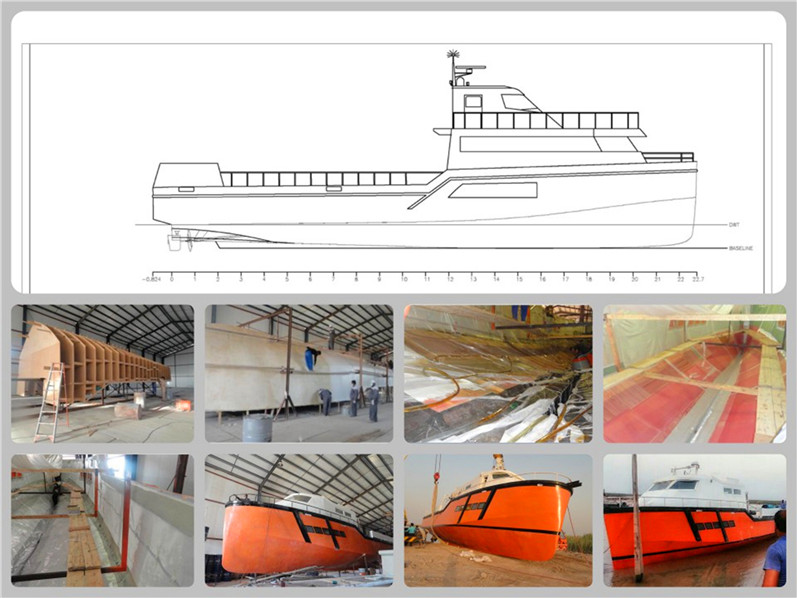

Pultrusion:

1. Improves cosmetics and surface smoothness

2. Improves fade and corrosion resistance

3.Superior abrasion and impact resistance

4.Reduces die wear and production shutdowns

5.Reduces fiber blooming

6.Fast wet-out / Processing speeds

7.Excellent conformability to complex shapes

Benefits:

Filament Winding/Open and Closed Molding:

1.Superior corrosion and stress corrosion resistance

2.Winds readily with less web breakage

3.Improves cyclic pressure strength of piping systems

4.Superior direct and reverse impact strength

5.Fast wet-out

6.Designed for optimum neck-down properties

7.Print blocker

Style | Unit | 111-00010 | 100-00010 | 039-00694 | 100-00000 | 115-00005 | 700-00005 | |

Shade: | Natural White | Natural White | Natural White | Natural White | Natural White | Natural White | ||

Basis Weight | (oz/y²) | 1.1 | 1.3 | 1.2 | 1.2 | 1.6 | 2.0 | |

(ASTM D3776) | (g/m²) | 37 | 44 | 40 | 40 | 54 | 68 | |

Caliper | (mil) | 11 | 12 | 12 | 10 | 14 | 20 | |

(ASTM D1777) | (mm) | .27 | .30 | .27 | .25 | .36 | .50 | |

Grab Tensile | Machine Direction | (lb) | 24 | 28 | 31 | 28 | 46 | 51 |

(ASTM D5034) | (kg) | 11 | 13 | 10 | 13 | 21 | 23 | |

Cross Direction | (lb) | 15 | 15 | 12 | 15 | 29 | 26 | |

(kg) | 7 | 7 | 7 | 7 | 13 | 12 | ||

Fiber Elongation @ Break | % | 25 | 25 | 25 | 25 | 25 | 25 | |

Fiber Melting Point | °F | 483 | 483 | 483 | 483 | 483 | 483 | |

(PFG Method) | °C | 250 | 250 | 250 | 250 | 250 | 250 | |

Standard Roll Length | (lin yd.) | 500 | 500 | 500 | 300 | 300 | 300 | |

3 in / 76 mm ID Core Tube | (lin mtr.) | 457 | 457 | 457 | 274 | 274 | 274 | |

Standard Roll Width | (in) | 57 | 48 | 60 | 48 | 60 | 48 | |

(cm) | 145 | 122 | 152 | 122 | 152 | 122 | ||

U.V. Resistance Comment | Good | Good | Good | Good | Good | Good | ||

Recommended Process | P | C | P | P | P | C | ||

P = Pultrusion | C | C | C | |||||

C = Open and Closed Molding | ||||||||