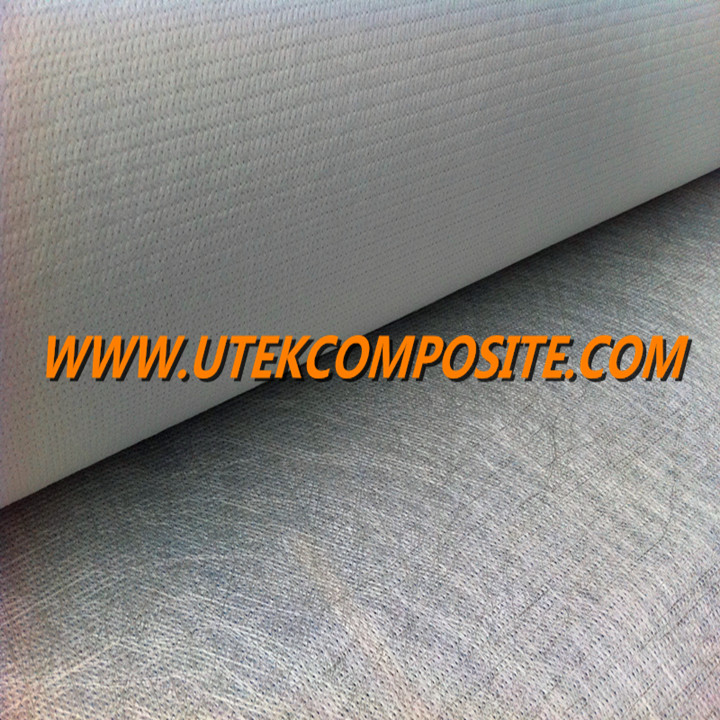

Veilmat: A Good Choice for Pultrusion

2016/07/07| View:836

CFM (continuous filament mat) is commonly used for pultrusion process. It has advantages of fast impregnation and high strength. However it’s easy to be jammed and broken in mold due to its thickness.

Now more and more fabricators like to use veilmat (polyester veil stitched to chopped strand) as substitute of CFM. Veilmat has the following strength compared to CFM:

1. Veilmat is stitched, so it’s thinner. Chopped length of fiber (same fiber as CFM) is 10cm. This gives higher strength to veil mat. Joints can be stitched or overlapped, which is easy for operation.

2. Polyester veil has feature of anti-aging & water resistant, and also gives good surface.

| CHANGZHOU UTEK COMPOSITE COMPANY CO.,LTD | ||||||

| COMPANY INTRODUCTION: | ||||||

| Company Name | CHANGZHOU UTEK COMPOSITE CO.,LTD | |||||

| Address | Fuhanyuan 1-814,Taihu Road,Changzhou,Jiangsu,China | |||||

| Contact Person | Name | Tel | Email ID | |||

| Manger | Gong Xiaojun | 0086 13357899376 | gong@utekcomposite.com | |||

| Manger | Irene Xi | 0086 13961156380 | irene@utekcomposite.com | |||

| Business Condition | Manufacture | Trading | ||||

| Consititution of company | Pvt.Ltd | |||||

| Annual turnover | USD10,000,000 | |||||

| Company Occupy Areas(M2) | 3000M2 | |||||

| Shower room Occupy Areas(M2) | 200M2 | |||||

| website | www.utekcomposite.com | |||||

| http://utekcomposites.en.made-in-china.com/ | ||||||

| Mainly Customer & Marketing | Europe,Asia,America,Middle East | |||||

| Mainly Product | Fiberglass chopped strand mat (powder and emulsion), stitch mat, combo mat, uni-direction and biaxial fabric, RTM core mat, woven roving, special products like Ar-glass roving, chopped strand, thin fiberglass fabric, SMC(sheet molding compound), fiberglass/polyester geogrid and geocomposite. fiberglass mica fabric for insulation. | |||||

| Sales Team | 15(University Graduates) | Product Team | 150 | |||

| Research & Development Team | 12 | QC Team | 8 | |||

| Certificate | ISO 9001 ,ISO 14001 ,SGS | |||||

| Give us a chance, and we' ll return you with satisfaction. | ||||||