Surface treatment and different density of PVC Foam

Surface treatment and different density of PVC Foam

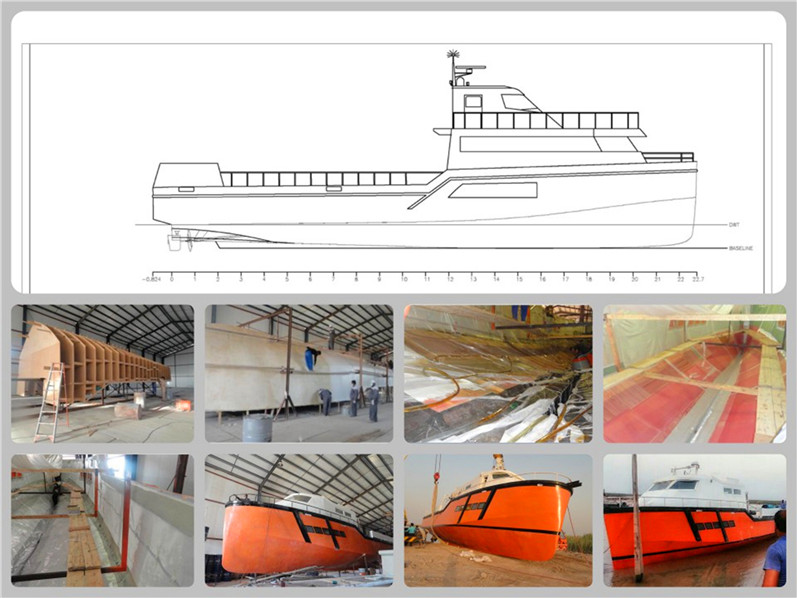

The selection of the appropriate post-processing technology will affect your product from all aspects such as the performance, cost and production efficiency. We have an advanced foam post-processing system and we will help you select the proper processing technologies such as cutting, grooving, perforation and so on.

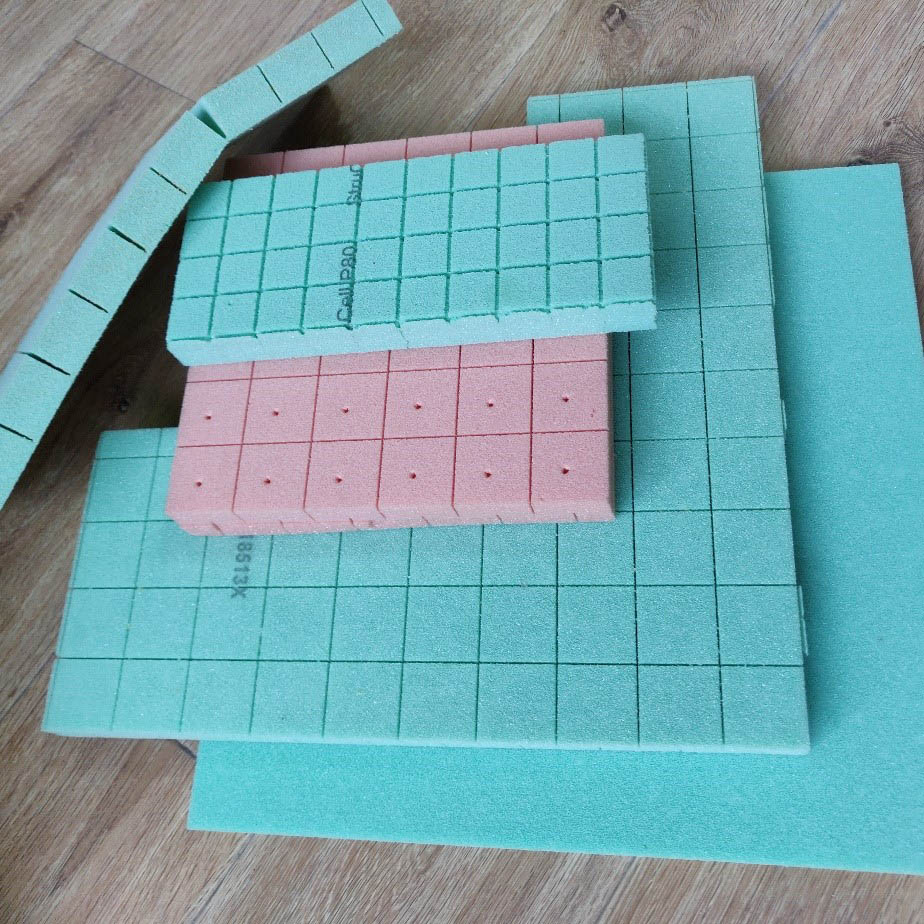

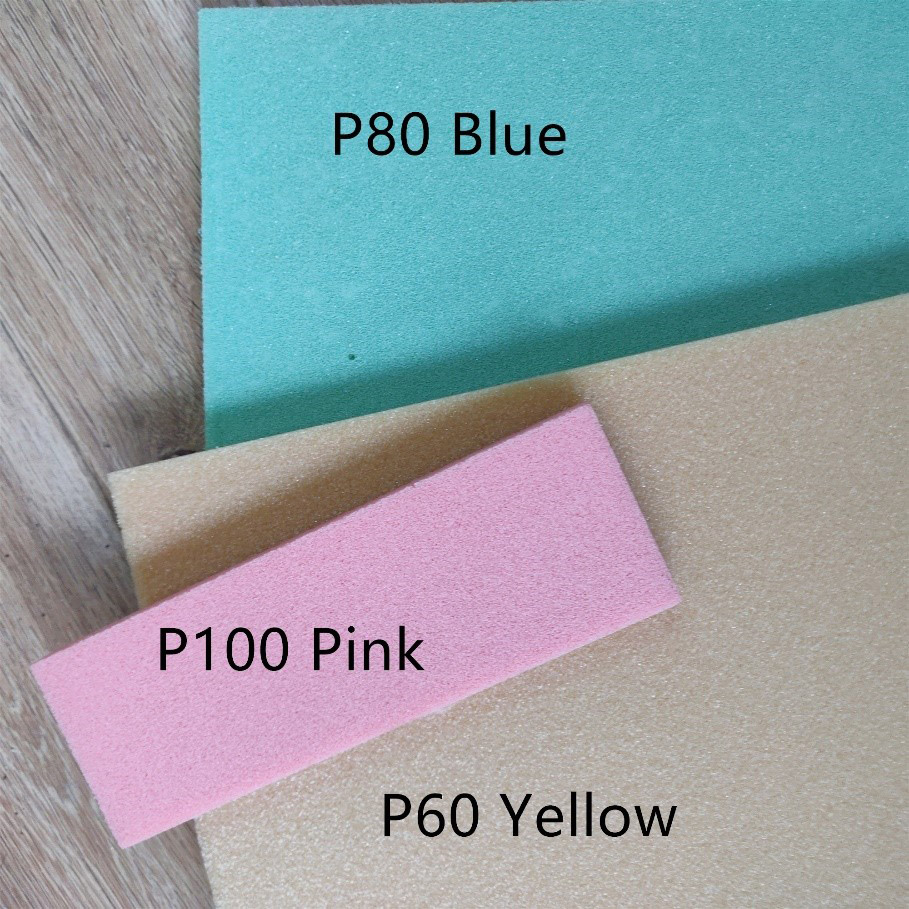

Depending on different lamination processes and requirements of surface curvature, we provide 6 kinds of foam cores (as shown in the following) with optimizing the amount of glue absorption:

![]()

Scheme | Type | Description | Molding Process |

| Flat Plate | There is no other post- processing. If you want curved surface, you can get it upon treating the flat plate by thermoforming. | Suitable for hand lay-up, compression molding and other processes of the flat plate with sandwich structure. |

| Scrim Foam | Small squares are formed by cutting on one side of the flat plate in both directions of length and width with gluing fiberglass mesh on the other side. | Suitable for products with curved surfaces. |

| Hyperbolic Plate | Cut both sides of the core material to the extent 55-60% of the thickness and the cutting positions are staggered. The amount of resin absorption is much less than that of scrim foam. | Suitable for the application with small curvature. |

| Perforated Plate | Perforate holes with diameter of about 2 mm on plates. You can adjust the diameter of holes according to the thickness and density of the core material. Trapped air formed in the process of lamination can be removed from the bottom of the core material by perforating holes. Also, the resins can flow from one side of the core material to the other side. | Suitable for hand lay-up, vacuum infusion, compression molding process to improve the adhesive strength. |

| Slotted Plate | Guide slots are set on the plate surface. Guide slots can be disposed in length or width direction on one side or both sides of the plate. The groove(s) can work as the flow path of resins and can remove the trapped air when using the resin vacuum infusion lamination process. | Suitable for vacuum infusion and compression molding process to produce products with large area. |

| Slotted Perforated Plate | 20mm. On the basis of slotted plates, perforate holes with a diameter of 2 mm in the slots that the spacing between every two is 20 mm in the length or the width direction of the plate. | It has features of the two above core materials, suitable for vacuum infusion, compression molding and vacuum bagging process to produce large-scale products. |

The expandable curved surface here refers to the plane that can be expanded to become a curved surface. When using a hyperbolic plate or scrim plate, the deformation of foam core materials takes place by adhesion of the two sides.

Hand lay-up is a simple, effective process. The molding can be achieved by single-face mold or room temperature curable resin in this method. Reinforcing materials are generally in the form of chopped strand mat or directional fiber fabric such as woven roving. The processing steps are quite simple. But this method is only one face to have a smooth appearance. Besides, it is limited to the immeasurability of the member thickness, fiber content, porosity or apparent mass of the back side.

Compression molding is a method of molding using heat and pressure in a closed mold cavity. It is characterized by smooth sides and precise control of thickness, mass and fiber content. But the process should be performed with negative-positive mold, so that the process cost is relatively high.

Resin infusion is the process that one kind or more liquid resin is injected into the closed mold cavity by pressure. The required pressure in the mold cavity can be realized by vacuum (vacuum assisted impregnation), gravity or with the help of exhaust pump or pressure vessel. Generally, vacuum is provided to assist the injection of resin in the common vacuum assisted injection technique. The realization of it is via single-face mold with the other side covering vacuum bags.