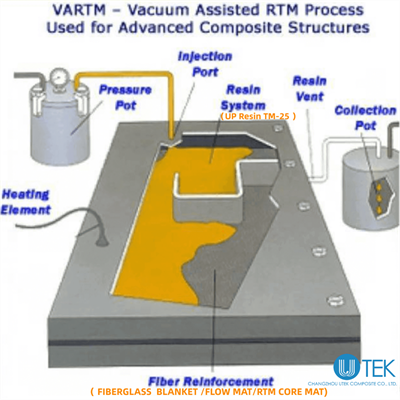

Raw Materials for RTM Process

We can provide following products for RTM Process:

1. Fiber Reinforcement

·Fiberglass Chopped Strand Mat

(300gsm, 450gsm, 600gsm)

Powder or Emulsion

Big width from 1000mm-3200mm

·Fiberglass Blanket/Fiberglass Flow Mat/ RTM Core Mat/ Fiberglass Sandwich Mat

(300/180/300, 300/250/300)

(450/180/450, 450/250/450)

(600/180/600, 600/250/600)

Chopped Strand Mat: 300gsm/450gsm/600gsm

PP tissue: 180gsm/225gsm/250gsm

·Fiberglass Multiaxial Fabric

( 0/90° Biaxial Fabric:LT600, LT800)

·Fiberglass Combo Mat

Customer Code | Product Name | 0º Roving Density (g/m²) | +90º Roving Density (g/m²) | Mat Density (g/m²) | Polyester Yarn Density(g/m²) | Total Weight(g/m²) |

CM1808 | LTM1808 | 300 | 300 | 275 | 875 | |

CM2408 | LTM2408 | 400 | 400 | 275 | 1025 | |

CM2415 | LTM2415 | 412.5 | 395 | 457.7 | 9.5 | 1274.7 |

Customer Code | Product Name | +45º Roving Density (g/m²) | -45º Roving Density (g/m²) | Mat Density (g/m²) | Polyester Yarn Density(g/m²) | Total Weight(g/m²) |

1708 | BXM1708 | 300.6 | 300.6 | 275 | 6 | 882.2 |

BM1808 | BXM1808 | 300.6 | 300.6 | 225 | 6 | 832.2 |

BM2408 | BXM2408 | 400.8 | 400.8 | 275 | 6 | 1082.6 |

2. Resin TM-25 for RTM( Unsaturated Polyester Resin)

·Pre-accelerated ·Long-gel time: 50.0-80.0 min 25℃

·Low viscosity: 0.14-0.18 Pa.S 25℃ ·Good glass fiber wettability

·Fast curing and air-drying properties

Welcome to inquiry!

Web: www.utekcomposite.com

Mail: info@utekcomposite.com