Categories

Pultrusion, winding, molding, hand lay-up, there are many processes people could deal with fiber reinforced material. UTEK as a leading raw material supplier, has our own VISION. Additive/subtractive manufacturing could be part of the futrue.

For additive manufacturing, we do have milled carbon fiber. For subtractive manufacturing, we need end mill.

Introduction

The end mill is a type of milling cutter designed to be able to cut axially and applicable in end milling, profile milling, tracer milling, face milling, and plunging. Even there are standard end mills available, pick up the right tool is still not easy.

Thus, before the simple introduction of parameters, three fundamental questions need to be answered:

1, What material you are going to work with.

2, What machine you are going to use.

3, What shape you are goint to achieve.

If not confident with your choice, please feel free to contact UTEK's sale representative. We do also accept customization.

Flute

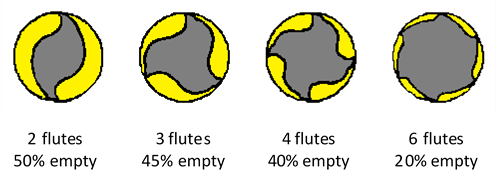

The function of a flute is to form blade and allow for chip formation and evacuation. In most times, chip evacuation is the key to select how many flutes are needed. The sectional graph of different end mills is below.

| 2 flutes | 3 flutes | 4 flutes | 6 flutes | |

| Pros | Large flute, can go axial direction easily. Low cutting resistance. | Large flute, can go axial easily. | High regidity. | High rigidity. Longer life span. |

| Cons | Low rigidity. | Hard to measure cutting diameter. | Small flute. | Small flute. Hard for clip evacuation. |

| Application | Most of the general applications. deep groove. | Most of the general applications. Fine finish. | Most of the general applications. Shallow groove. | Superhard material, Shallow groove. |

Nose

There are three fundamental nose shape, flat nose, ball nose and bull nose. Picek up the right nose for the right job is one milestone to your finished shape.

| Flat nose: Can be used to mill flat surfaceboth vertically and horizontally. |

| Ball nose: Can be used to mill curved surface. | |

| Bull nose: Can be used to mill groove with fillet corner. |

Coating

End mill evolves with different coating. Hardness, working temperature, frictional coefficient and even color is not the same.

But choose the right coating is not easy. Here is a simple coating/performance chart (common coating only). Hope it can do some help.

| Coating | Coating Hardness (GPa) | Frictional Coefficient | Working Temperature (ºC) | Color | Application/Material |

| TiN | 23 | 0.4 | 600 | Gold | Low speed milling |

| TiAlN | 29 | 900 | Grey | High temperature alloy, die steel | |

| TiSiN | 41 | 0.3 | 1200 | Copper | Stainless steel, quenched steel |

| Diamond | 98 | 650 | Grey | Carbon fiber, graphite, ceramic |

Size Chart

| Cutting Diameter | Flute length | Handle Diameter | Total Length | ||

| d | l | D | L | ||

| 1.0×3×4D×50L | 1 | 3 | 4 | 50 |

| 1.5×4×4D×50L | 1.5 | 4 | |||

| 2.0×6×4D×50L | 2 | 6 | |||

| 2.5×8×4D×50L | 2.5 | 8 | |||

| 3.0×8×4D×50L | 3 | 8 | |||

| 3.5×10×4D×50L | 3.5 | 10 | |||

| 4.0×11×4D×50L | 4 | 11 | |||

| 3.0× 8×6D×50L | 3 | 8 | 6 | ||

| 3.5×10×6D×50L | 3.5 | 10 | |||

| 4.0×11×6D×50L | 4 | 11 | |||

| 4.5×13×6D×50L | 4.5 | 13 | |||

| 5.0×13×6D×50L | 5 | 13 | |||

| 5.5×13×6D×50L | 5.5 | 13 | |||

| 6.0×15×6D×50L | 6 | 15 | |||

| 7.0×16×8D×60L | 7 | 16 | 8 | 60 | |

| 8.0 ×20×8D×60L | 8 | 20 | |||

| 9 ×20×10D×75L | 9 | 20 | 10 | 75 | |

| 10×25×10D×75L | 10 | 25 | |||

| 11×25×12D×75L | 11 | 25 | 12 | ||

| 12×30×12D×75L | 12 | 30 | |||

| 14×35×14D×100L | 14 | 35 | 14 | 100 | |

| 16×40×16D×100L | 16 | 40 | 16 | ||

| 18×45×18D×100L | 18 | 45 | 18 | ||

| 20×45×20D×100L | 20 | 45 | 20 |