Application of aramid fiber in automotive recycled rubber hose

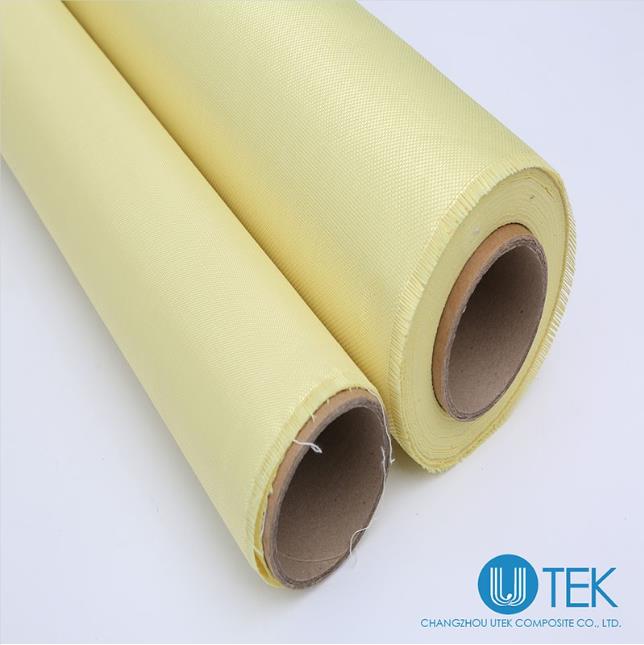

With the development of society, aramid fiber is respected in various fields because of its high strength, heat resistance, chemical resistance, insulation, toughness, and other characteristics. This is also true in automotive recycled rubber hoses. Using recycled rubber to produce automotive hoses can effectively reduce costs, such as fuel hoses, heater hoses, power steering hoses, and other automotive hoses containing recycled rubber can use aramid fiber as the most reinforcing material to further improve the overall performance of automotive hoses. Today, we share the application of aramid fiber in the automotive recycled rubber hose.

1. First of all, we need to understand. The performance of the skeleton material in the hose should have.

The vulcanization method of the hose has steam direct vulcanization method, salt bath vulcanization method, hot oven vulcanization method, etc. The vulcanization process and the hose's performance determine that the skeleton of the recycled hose needs to have high-temperature, high-pressure, high strength, and good fatigue resistance, and the shrinkage rate can not be too large, easy rubber bonding, and other characteristics.

2. Aramid fiber in the application of automotive recycled rubber hose.

(1) power steering hose, the use of aramid fiber as a reinforcement layer can improve the high pressure, high temperature, and durability of the hose, the use of high-strength aramid can ensure the pressure under the premise of the appropriate reduction in the number of layers of fiber reinforcement layer, thereby reducing the rigidity of the hose, reduce the noise generated during the use of the hose.

(2) fuel regeneration hose is a fuel tank refueling hose. The hose is assembled on the car fuel tank, using a relatively low temperature. Using aramid fiber as the skeleton material can enhance the hose's performance.

(3) Engine cooling circulation system hose is a soft connection between the engine jacket and radiator to circulate cooling water. Adding aramid fiber to the hose can improve the hose's pressure, temperature, and durability performance.

In general, aramid fiber in automotive recycle hoses can improve the pressure resistance, heat resistance, and durability of automotive hoses, thus improving the overall performance of automobiles. In practice, aramid fiber must be treated and processed to improve the viscosity enhancement in the design formula appropriately.

The above is about the application of aramid fiber in automotive recycle hoses. If you need to know more, welcome to contact us!